1.Structural differences

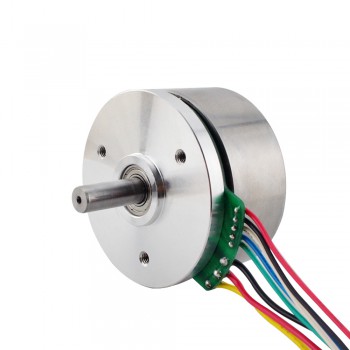

The rotor of an internal rotor motor is assembled inside the motor housing and connected to the motor’s output shaft. The rotor of an external rotor motor is located outside the motor, and the output shaft is also transmitted by the rotation of the rotor outside the motor.

2.Differences in characteristics

1.Internal rotor motors are usually more compact and have higher power density because the motor components are more compact. External rotor motors are usually easier to maintain because the rotor components are outside the motor and are easy to maintain and replace.

2.Internal rotor motors can withstand higher pressures and torques because their rotors are more secure inside the motor. However, external rotor motors can rotate faster because their rotors are lighter.

3.Internal rotor motors tend to have longer life and higher efficiency than external rotor motors. This is because the rotor runs inside the motor and is not affected by external physical factors. The centripetal force and other physical phenomena generated by the external rotor motor when rotating at high speed may reduce the motor efficiency and life.

3.Application differences

Internal rotor motors are often used in high-performance applications such as aircraft, rockets, high-speed trains, etc. This is because internal rotor motors have higher power density and can provide greater output power. External rotor motors are usually used in smaller applications, such as household appliances, small machinery, etc. This is because they are easier to maintain and replace and have better reliability.

4.Summary

Both internal rotor motors and external rotor motors are important types of motors. According to different application environments and requirements, you can choose the appropriate motor type. Internal rotor motors are suitable for high-load and high-performance applications, while external rotor motors are suitable for smaller and simpler applications. In addition, internal rotor motors usually have higher efficiency and longer life, but external rotor motors are easier to maintain and replace.